Our techniques・proposal

The accumulation of ideas to combine new elements with technology accumulated through the manufacture of fluid equipment parts and the idea of “trying it out” by each and every employee leads to the ability to make proposals to our customers.

Production technology

Together with our partner companies, we offer technical proposals that include cost, quality, and the environment, such as proposals for centralization and weight reduction by integrating cutting and sheet metal technologies, man-hour and energy reduction by eliminating welding, specification changes from casting to forging, and proposals for two-layer stainless steel materials to provide corrosion resistance.

01Work automation by robot

For the past 20 years, we have been focusing on automated accounting, and in the pursuit of profits for our customers, we have realized the development of robot labor-saving systems in-house, without relying on manufacturers.

We have built a flexible production system that can handle increased production, and many products have been created through automation, and our customers are now satisfied with our prices and delivery times!

02Customizable ordering application

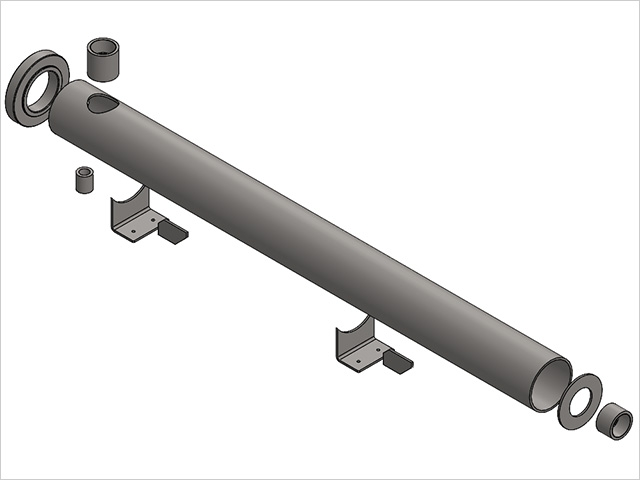

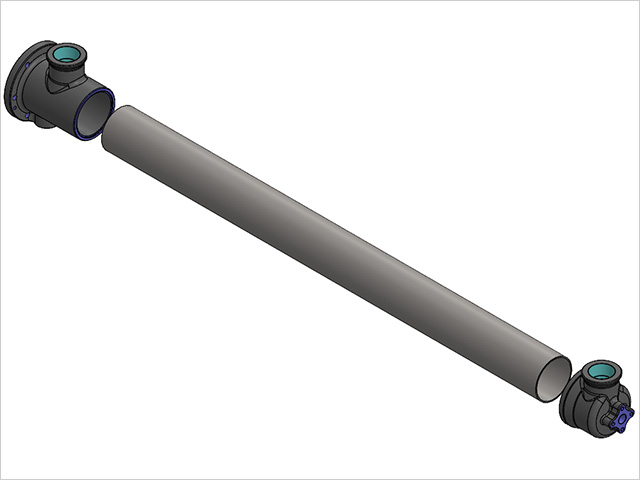

Custom-made OEM manufacturing of fluid equipment ( valves )

Depending on the nature of the fluid used, the pressure and temperature as the environment in which it is used, and the material and processing method, We can manufacture parts and assemble them according to the customer’s order.

Management is established based on various combinations of materials and processing methods for functional parts consisting of several dozen items, each of which is made to order, and can handle everything from part fabrication, part quality, inventory and allowance management, and kitting to total assembly, pressure resistance testing, and non-destructive testing.

Delivery can be made in about one month if we make an agreement with the customer to pick up the parts inventory.

03Development of digitization and visualization tools

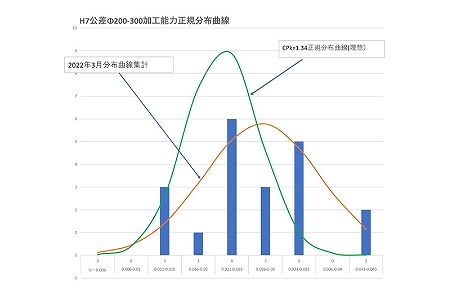

P-FMEA, process capability management, and tolerance averaging to achieve CPK 1.33

P-FMEA helps analyze potential failures of a particular process at the operational level.

We will clarify the position we are aiming for on the shop floor side by incorporating methods that can be visually understood using our digitalization and visualization tools.

We also use in-house training rooms to see the actual movement of products, assemble and disassemble them, and conduct classroom lectures to understand the critical parts of the product and help improve quality.

Techniques

Our technological strength is the fusion of general-purpose and high-technology.

We are working on technological development that is one step ahead of the times by fusing conventional general-purpose technologies with high-tech technologies, as well as the transformation of ideas born from within those technologies.

In the area of materials, we combine our proposals for raw materials, castings and forgings, and processing technologies.

01Developed 6-axis multitasking machine by modifying multitasking machine

The machining process, which used to take 150 hours when using only large-size machining, could be done by adding a servo motor and machining at different angles.

The idea was to convert the machine into a multitasking machine with an additional A-axis.

The machine can perform lathe turning from various angles, and its technical capability to create its own programming has enabled the company to reduce the machining time to 15 hours.

02Obtained patent for screw rotor processing technology through joint research with Tohoku University

The machine can perform lathe turning from various angles, and its technical capability to create its own programming has enabled the company to reduce the machining time to 15 hours.

03Installed the latest bender machine and a combined laser processing machine and punch press machine.

Bender machines can provide customers with comprehensive advantages in prototyping and small and medium lot, mass production, and laser punch combined machines enable not only high-speed laser cutting but also forming processing, offering customers not only production cost reductions but also cost reductions between processes.

In particular, by being involved from the design stage, we are able to propose new technologies and new ideas for manufacturing products with even lower costs. We are ready to take on the challenge of manufacturing products that we have given up on or have not been able to do before.

04Human resource development to acquire specialized knowledge and skill

Filled with the energy of employees who are eager to learn the latest technology.

We believe that the development of good human resources is one of our technological strengths.

We also fully support our employees’ education system to further develop over the years the qualifications that require specialized knowledge.

| Qualification acquisition results | Successful candidate |

|---|---|

| 1st grade Certified Skilled Professional of Machining (Numerically controlled lathe) | 2 person |

| 2st grade Certified Skilled Professional of Machining (Numerically controlled lathe) | 6 person |

| 1st grade Certified Skilled Professional of Machining (Machining center) | 2 person |

| 2st grade Certified Skilled Professional of Machining (Machining center) | 3 person |

| 2st grade Certified Skilled Professional of Machining (Machine inspection work) | 2 person |

| Non-Destructive Testing Personnel Certification (Penetrant Testing Level 2) | 1 person |

| Non-Destructive Testing Personnel Certification (Penetrant Testing Level 1) | 3 person |

| Vocational training instructors | 2 person |

| Stainless steel welding skill person (TN-V) | 2 person |

VA / VE proposals

We catch the voice of our customers through manufacturing, and through analysis, ideas, and teamwork, we proactively make mutually beneficial proposals that go beyond cost reductions to improve quality,

production efficiency, and other areas. We have a track record of making various proposals such as weight reduction and reduction in the number of parts.

*Due to confidentiality agreements with our customers, we are unable to publish detailed processing examples.

Example

01Practical application in 2017 Joint development and practical application with a pump manufacturer

Lighter, smaller, and more cost-effective pumps mounted on agrochemical sprayers

- 【Weight】

- 3.2kg→2.7kg Approx. 14% reduction

- 【Size】

- Length 144mm→ Length 132mm Approx. 14% miniaturization

Example

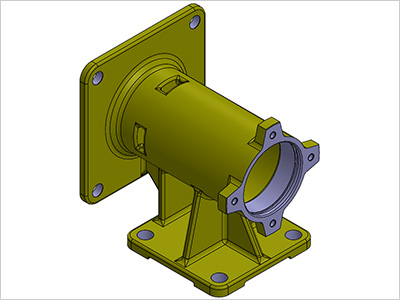

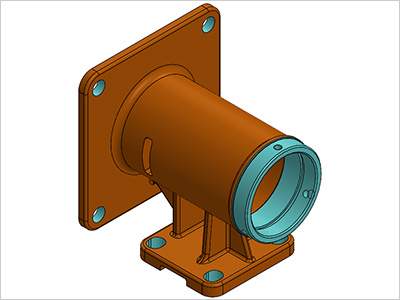

02Commercialization in 2019 Joint development and commercialization with a semiconductor manufacturing equipment manufacturer

Reduction in the number of parts by converting products mounted on chillers (liquid temperature controllers) to lost wax.

The number of parts and man-hours for welding were reduced by changing from fabrication of each part + welding to lost wax + welding.

Number of parts : 10

Number of parts : 3

Example

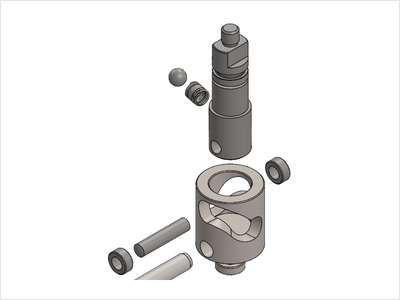

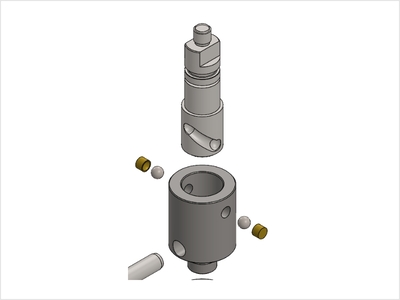

03Proposal to a valve manufacturer to reduce the number of rotating body structural parts

The current manufacturer’s product has an issue with the rotating mechanism of the handle that does not work smoothly.

There are structural and machining limitations, and there is concern that the product will be expensive.

Conventional Products

Products developed by production technology

Our production engineering department proposed cost reduction by simplifying the structure,

simplifying the machining, smoothing the rotating mechanism, and reducing the number of parts.