Machining example of lizuka&CO., LTD,

We manufacture parts including pumps and valves for fluid equipment as well as parts for vacuum equipment and medical equipment, and are involved in diverse fields such as medicine, semiconductors, energy, chemical plants, and aerospace.

Latest machining technology

We understand the strengths of a wide variety of processing equipment and refine the latest processing technologies to create innovative processing techniques.

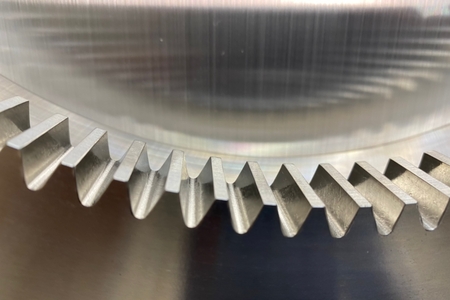

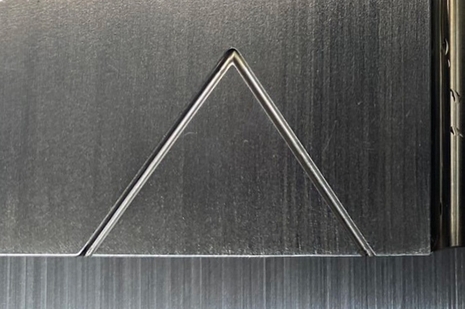

01Gear machining technology using a combined NC lathe (skiving gear machining)

- Material:S45C

- M:3.0

- Number of teeth:102

- Cutting edge:φ300

- Tooth Thickness:25.0mm

- Processing Time : 12 minutes

- Processing accuracy:Old JIS 4 class

- Material:SUS630

- M:3.0

- Number of teeth:102

- Cutting edge:φ300

- Tooth Thickness:25.0mm

- Processing Time : 18 minutes

- Processing accuracy:Old JIS 4 class

Gear machining that was previously performed on a dedicated machine is now integrated into a single multitasking machine.

Cost and lead time can be reduced.

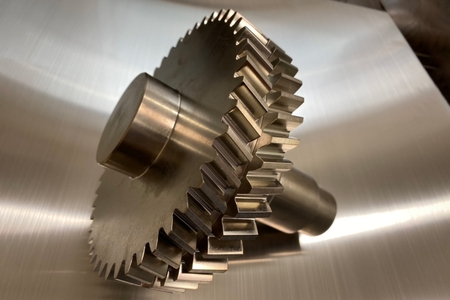

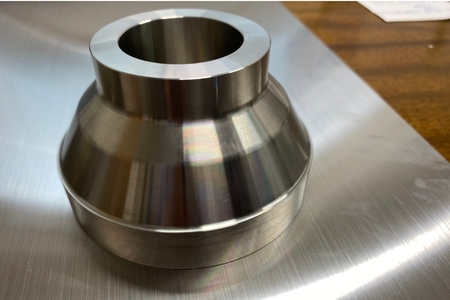

02High-precision gear-cutting integral shaft

- Material:S45C

- M:8.0

- Number of teeth:23

- Cutting edge:φ200

- Processing time:10h

- Processing accuracy:Equivalent to former JIS Class 1

- Shaft gear concentricity:0.02

The product, which was conventionally welded to the shaft, is manufactured as a machined one-piece unit.

03High-precision gear-cutting integral shaft

- Material:S45C

- M:4.0

- Number of teeth:45

- Cutting edge:φ200

- Processing time:20h

- Processing accuracy:Equivalent to former JIS Class 1

- Shaft gear concentricity:0.02

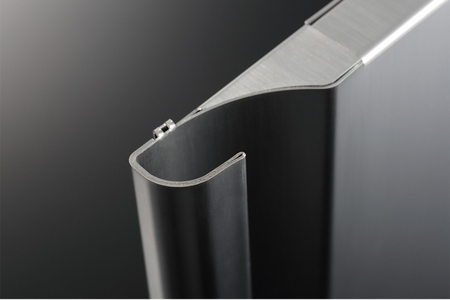

04Thin-walled pipe processing (ultra-thin-walled pipe with integrated cutting)

Ultra-thin wall machining of t = 0.08 mm with integrated cutting without welding

- Material:SUS304

- Surface roughness:Inner diameter Ra1.2/Outer diameter Ra0.8

- Circularity:Inner diameter φ19.978L/Circularity : 0.03/Outer diameterφ20.145/Circularity 0.014~0.025

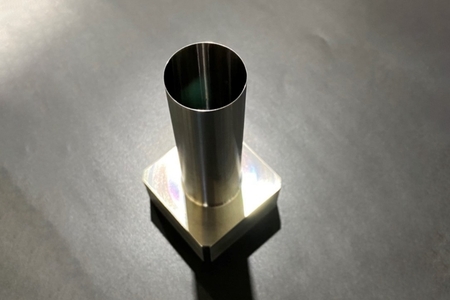

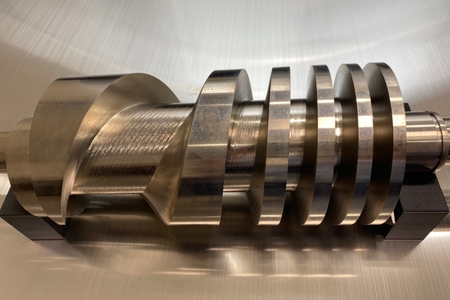

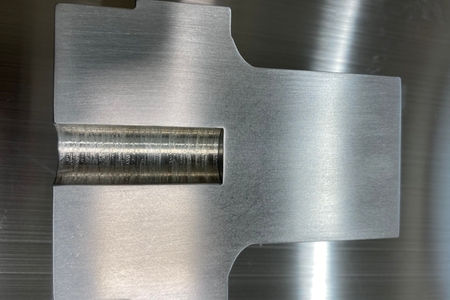

05Unequal-to-equal lead screw shaft for vacuum pumps

- Material:S45C

- Approximate dimensions:φ130-450L

- Inequal-to-equal lead screw shaft for vacuum pumps:0.01

- Tooth surface accuracy:±20μ

Continuous machining of equal and unequal leads without joints by controlling the rotation speed and angle unique to 6-axis machining and employing a special tool.

Cross sections perpendicular to the axis can be produced as desired.

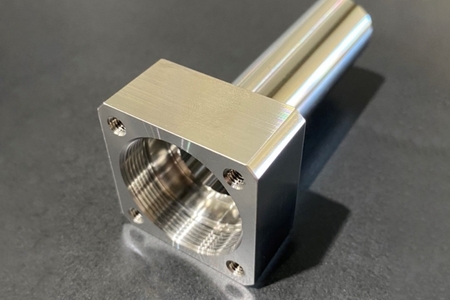

06Body processing for micro flow control Fine hole processing (high aspect ratio processing)

- Material:SUS316L

High surface roughness and step-free joints reduce post-processing such as buffing.

Drilling of extremely small, deep holes is also possible at low cost and with high accuracy, without EDM machining.

Simultaneous machining minimizes burrs.

Tolerance hole with small diameter

This is an example of cross-hole drilling of φ1 with a depth of 20 mm (20D).

The cross-hole has no steps and is treated at the same time as machining to minimize burrs.

Smooth connection with full R at the tip of large diameter hole

This is an example of machining a φ10 cross-hole with a depth of 80mm (8D).

Surface roughness: Ra 0.5 to 0.6

Smooth joints with R that do not obstruct fluid flow.

Smooth connection with full R at the tip of small diameter hole

This is an example of joint hole drilling with φ1 full R tip with a depth of 20 mm (20D).

The φ1 tip is smoothly connected with a full R of R0.5.

The actual product is machined by a robot in unmanned operation.

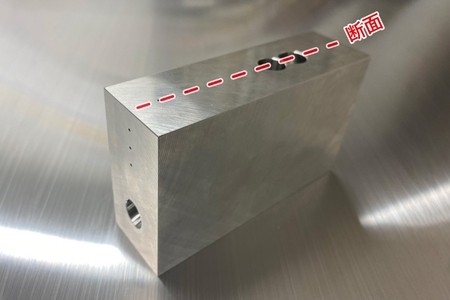

60D depth machining from one direction Crossed holes with minimal misalignment

This is an example of machining φ1 extra-deep hole of 60mm (60D) depth.

Straightness: 0.03

Machining of a 60D ultra-deep hole is also performed simultaneously with machining to finish to high precision.

Welding processing technology

We provide high level welding technology by skilled welders.

We understand pumps and valves well, and we perform welding repair of castings consistently.

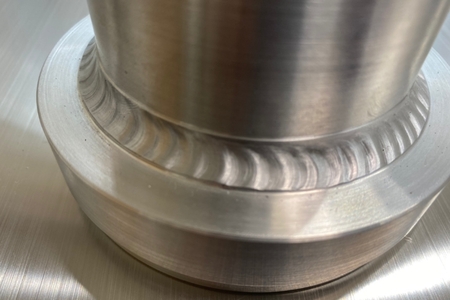

01Satellite welding to sliding parts of special pumps and valves

- Improve wear resistance of valve flow paths

- Improve wear resistance of divider valves

- Improve wear resistance of seating surfaces of chuck valves

- Improve wear resistance of valve seal rings

thereby reducing the workload of the finishing process.

02Aluminum welding

Uniform bead from start to finish for a beautiful appearance.

Firmly fused welds with no blowholes or cracks.

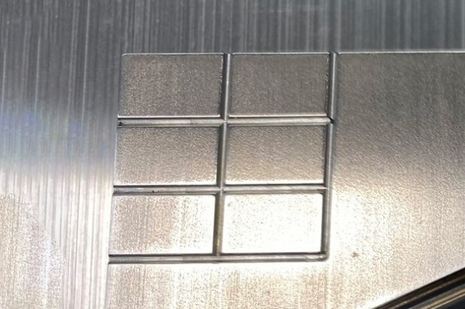

Sheet metal working technology

We provide weldless processing technology without the need for special dies by introducing state-of-the-art machinery and equipment.

Others

We are pleased to introduce you to products that integrate our technologies.

01Control box

- Material used:SUS304 t1.2、t2.5

- Min:W250xH404xL150

- Max:W600xH800xL150

Gaps between each part are minimized by the fusion of high-precision laser cutting and bending.

The joints incorporate simple, puzzle-shaped fixation to eliminate welding.

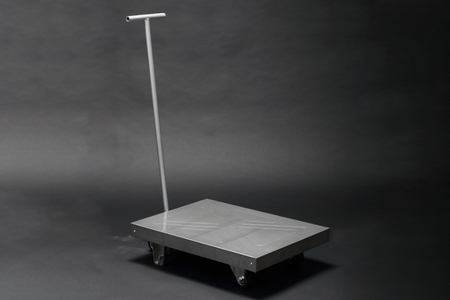

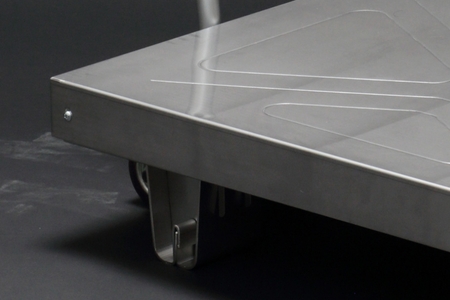

02Bogie

Material:SUS304 t1.2、t2.5

The body of the cart is completely weldless manufacture.

The top plate is roller bead processed by a multitasking machine to increase strength.

The complex shape of the legs is realized by bending without using a special die.

The handle part is detachable and designed for space-saving transportation and storage.

03Tool box

Material used: SGCC t1.0

The lid and body are each constructed from a single board.

The hinges are integrated, eliminating the need for separate purchase and enabling low-cost production.

04Japan don

Andon made in an ironworks.

It expresses “Story with four seasons in Japan” with ultra-precision laser processing technology.

Three manufacturing companies in Niigata have thoughtfully created this product, taking advantage of the qualities of metal and the beauty of light reflected by paper.