Our integrated production system ensures high quality products

Founded in November 1953, the company has been in business for 69 years.

The company's origins lie in the repair of pumps, valves, and other fluid components used in oil refineries. Currently,

The strength of our company lies in our accumulated know-how,

including VA/VE proposals, which we have accumulated through our continuous efforts to benefit our customers.

We have a spirit of challenge without fear of failure, and under our company motto,

"Challenge - Enthusiasm - Service," we are always striving to improve as a company.

Supply chain

In addition to our extensive production facilities and integrated production system to meet customer needs, we also offer optimal material selection, processing method selection, and shape proposals, leading to product cost reductions and productivity improvements.

Material procurement

We procure high-quality, optimal materials. domestic and international steel networks

Procurement of material

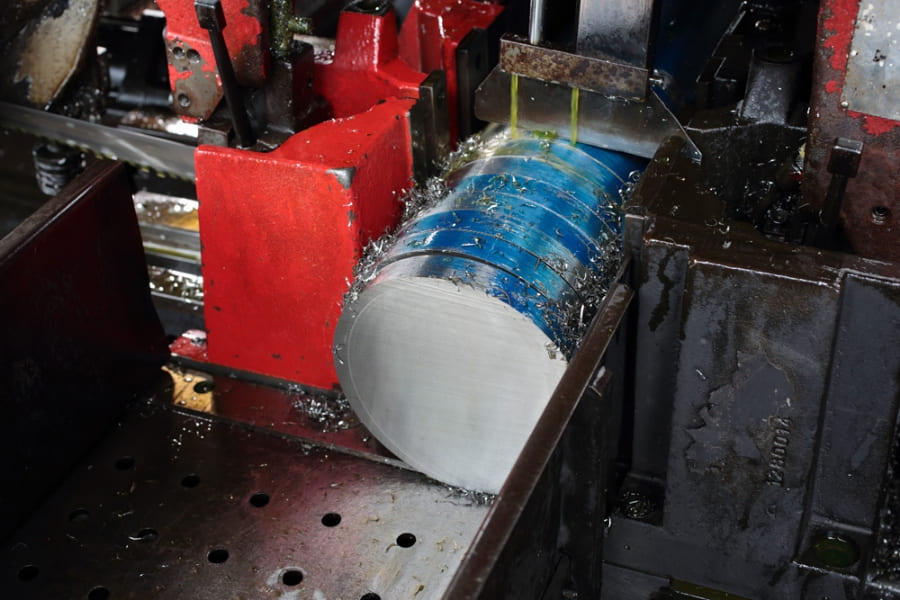

Processing

Welding, precision cutting, sheet metal processing and assembly, etc. various types of processing are available.

IIZUKA & CO., LTD. Processing

Special processing

We have many subcontractors in Kashiwazaki and other cities.

Special treatments such as surface treatment and heat treatment are also available.

Assembly

We provide a wide range of integrated production services from assembly to inspection from processing of products such as pumps for general industrial use

Assembly

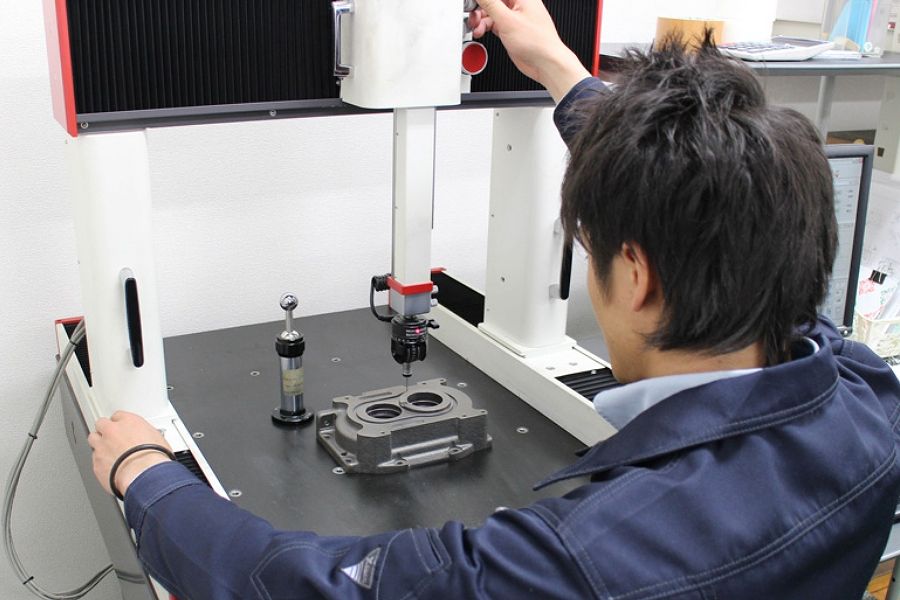

Quality control

We implement rigorous quality control and have established ISO 9001-compliant quality systems at all of our factories.

Our quality controlsProcessing examples

Job and Internship Information

We plan to offer hands-on experience and factory tours.

Those who are interested in manufacturing and want to acquire skills are welcome to join us

Business Calendar

| 2025.07 | ||||||

|---|---|---|---|---|---|---|

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

| 01

| 02

| 03

| 04

| 05

| ||

| 06

| 07

| 08

| 09

| 10

| 11

| 12

|

| 13

| 14

| 15

| 16

| 17

| 18

| 19

|

| 20

| 21

| 22

| 23

| 24

| 25

| 26

|

| 27

| 28

| 29

| 30

| 31

| ||

【Business Hours】8:00~17:00

Please contact us on working days for advice and inquiries.

We provide daily news and other information.

Follow us and check it out

JAPAN DON

The advantages of metal and the beauty of light reflected by paper.

~JAPAN DON~ is a product that we challenged as a new manufacturing by introducing a laser processing machine and bending machine capable of fine workmanship at Iizuka Ironworks.

View original siteAddress

Headquarters

3-15-16, Handa, Kashiwazaki-City,

Niigata 945-0812 Japan

TEL: +81 (0)257 23 5611/

FAX: +81 (0)257 23 2813

Manufacturing Factory,Sheet metal assembly Factory,Quality Logistics Factory

931-42, Karuigawa, Kashiwazaki-City,

Niigata 945-1355 Japan

(The 1st Manufacturing Factory)

TEL: +81 (0)257 41 5551/

FAX: +81 (0)257 41 5501

(The 2nd Manufacturing Factory,Sheet metal assembly Factory)

TEL: +81 (0)257 41 5551/

FAX: +81 (0)257 41 5501

(Quality Logistics Factory)

TEL: +81 (0)257 41 5703/

FAX: +81 (0)257 41 5704